By Eric Gersh, General Manager - Switchgear

Metal-clad switchgear is typically considered top-of-the-line equipment, offering the most safety features, higher current interrupting, and more voltage options. All these options also mean that the equipment is usually larger in overall footprint. Meaning it costs significantly more than non-metal-clad switchgear or metal-enclosed switchgear. When deciding what is best for your new build or equipment upgrade, you’ll want to take the differences into consideration.

How IEEE Defines Metal-enclosed Switchgear

A switchgear assembly completely enclosed on all sides and top with sheet metal (except for ventilating openings and inspection windows) containing primary power circuit switching and/or interrupting devices with buses and connections and possibly including control and auxiliary devices. Access to the interior of the enclosure is provided by doors or removable covers. Metal enclosed power switchgear may include the following equipment:

- Disconnect switches (to interrupt or to isolate)

- Power fuses (current-limiting or non-current-limiting)

- Fixed-mounted power breakers

- Bare bus and connections

- Fixed-mounted instrument transformers

- Control wiring and accessory devices

The disconnect switches and power fuses may be stationary or removable, also known as drawout. When removable, automatic shutters (that cover primary circuit elements when the removable element is in the disconnected, test, or removed position) and mechanical interlocks should be provided for proper operating sequence.

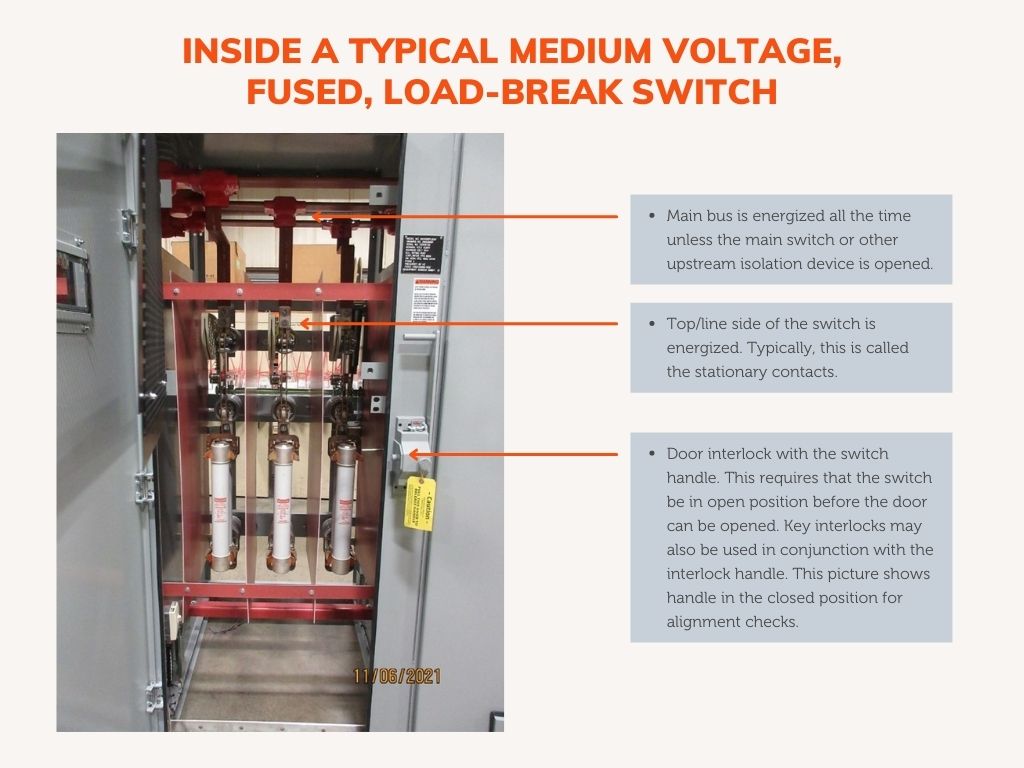

This equipment is the standard equipment that’s been around since the beginning of electrical distribution. Today, it primarily describes load-break and non-load-break switches, fixed mounted breakers (with or without an isolation switch), and most types of motor control. Working on this type of equipment requires high levels of safety precautions and knowledge. This is because the main bus can be energized in any section if the upstream isolation device remains closed. Metal-enclosed switchgear is typically less expensive, has a smaller footprint, and can offer a wide variety of bussing and connections options compared to metal-clad switchgear.

Above is a typical outdoor, 15kV switch lineup with an incoming and bus transition section. The main switch energizes the incoming section regardless of its position. The main switch or the upstream isolation device will then open to de-energize each of the 4 feeder switches

How IEEE C37.20.2 Defines Metal-clad Switchgear

Metal clad power switchgear is characterized by the following necessary features:

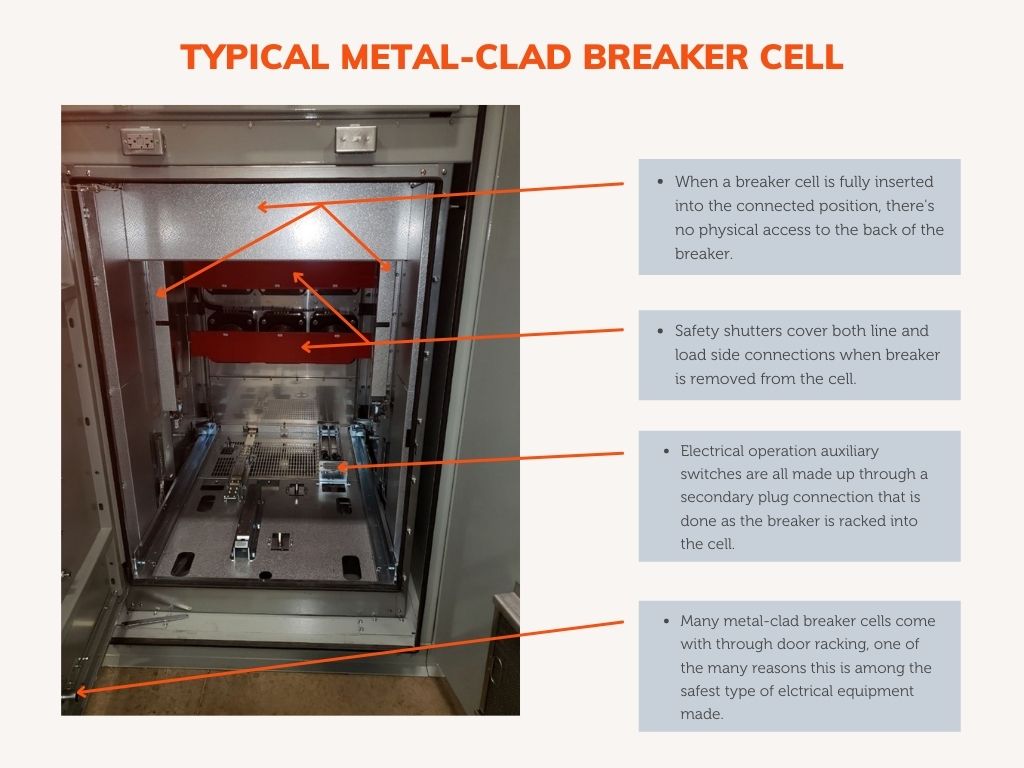

- The main switching and interrupting device is removable (drawout), arranged with a mechanism for moving it physically between connected and disconnected positions. Self-aligning and self-coupling primary disconnecting devices equip it, along with self-connecting control wiring connections.

- Grounded metal barriers completely enclose every major component of the primary circuit that can be de-energized, with no intentional openings between compartments. Specifically included is a metal barrier in front of, or a part of, the circuit interrupting device to ensure that when in the connected position no primary circuit components are exposed by the opening of a door.

- All grounded metal compartments enclose live parts.

- Automatic shutters cover primary circuit elements when the removable element is in the disconnected, test, or removed position.

- The insulating material covers primary bus conductors and connections throughout.

- Mechanical interlocks are provided for the proper operating sequence under normal operating conditions.

- Grounded metal barriers isolate instruments, meters, relays, secondary control devices, and their wiring from all primary circuit elements, except for short lengths of wire (such as those found at instrument transformer terminals).

- The door that allows insertion of the circuit-interrupting device into the housing can function as an instrument or relay panel and also grant access to a secondary or control compartment within the housing.

An Important Note

One thing to keep in mind is that when the breaker is open and in the disconnect position, it does not expose any live bus unless safety barriers are physically opened. Once verified as ‘dead,’ any load-side bus is completely de-energized and safe to contact. This can by ay using some type of hot stick or live line indicator. Personnel working on metal-clad switchgear still have to use care when working in a breaker cell. This is due to the presence of control power that can come from multiple sources, as well as any main bus connected PT/VT’s.

Below are images showing the major parts of metal-clad equipment.

At Southwest Electric Co, we offer solutions for both metal-clad and metal-enclosed switchgear types. Whether you are looking for new switchgear or want to repair or refurbish your existing lineup. Learn more on our switchgear product page or contact us for a custom solution for your facility today.

Equipment maintenance is key to extending the life of your equipment. Be aware of the Top 5 Switchgear Maintenance Must-do’s.

When it is time to upgrade your electrical system, read our article, 3 Effective Electrical System Upgrades.