By Ron Nicholas, Head of Service Operations

To ground, or not to ground – that is the question. There are many factors to consider before selecting the best method of neutral grounding for your electrical system. This article discusses the requirements and techniques of four different methods of system grounding to help you choose which one is best for your needs.

Background:

At the beginning of the 20th century, the methods for system grounding were limited to basically only two options: solidly grounded or ungrounded systems. Both options had their advantages and disadvantages as follows:

Solid Grounding has its advantage of high fault current levels to easily drive protective devices into operation. However, these high fault currents led to undesirable high energy arcing in hazardous areas and could develop service continuity concerns for critical service loads. Both of these grounded system disadvantages led early power system engineers to consider ungrounded systems.

Ungrounded systems had the perception that they would provide better service continuity through the first ground fault and there is some data to support this conclusion. Unfortunately, transient system overvoltage can also result from restrikes to ground in this configuration. Because of the downsides, neither method could provide the ideal protection and service continuity for all possible circumstances.

Other alternative methods available to the system designer have replaced this “to ground or not to ground” debate over the years, providing better overall protection and service continuity. These other methods we will cover in this discussion.

Current Methods of Power System Grounding

It is important to start with a definition of solid grounding.

Solid grounding serves as a permanent and continuous conductive path to “earth” with sufficient ampacity to carry any fault current, of sufficiently low impedance to limit the voltage rise above ground and facilitate the operation of the protective devices in the circuit. These functions reduce shock hazards to personnel and limit damage to equipment.

Solidly grounded systems are by far the most commonly found in the industrial and commercial power systems today. In many cases, it is mandated by NEC Article 250, and in other cases, it is selected based on pure economics. This is especially true where low voltage (<600 volts) single-phase loads are applied to the three-phase system as is typical in commercial buildings. In these single-phase loading cases, a solidly grounded neutral is required for the system to perform properly.

1. Ungrounded Systems

Organizations use this system configuration when service continuity is their main concern. In this design, a line to ground fault can remain on the system without causing a service disruption while the fault is located and cleared. The longer the first fault remains on the system, the greater the chance of a second fault occurring due to the 73% higher voltage impressed on the rest of the systems insulation. Transient over voltages from restrikes can also create problems from this system configuration. Today, better overall protection can be achieved in some cases with properly designed High Resistance grounding (discussed below). It is an important safety issue to keep in mind that an ungrounded system is still effectively coupled to ground through the capacitance network of the system, but personal shock hazards can still exist.

2. Low Resistance Grounded Systems

In this method, engineers insert a resistor between the system neutral point and ground to limit the fault current to values that are high enough to operate protection devices but not high enough to damage equipment and cause significant economic impact. Since the grounding impedance is resistive, transient over voltages are not an issue. Engineers cannot use this method for low voltage industrial and commercial systems because the faults do not allow reliable detection.

3. High Resistance Grounded Systems

High Resistance grounded systems are very much the same as the low resistance grounded ones apart from the magnitude of the resistance. In this case, the resistance is chosen to limit the typical fault current to 10A or less. With this low fault magnitude, no appreciable damage is done to equipment and the circuit can remain in service until cleared. If engineered correctly, it can also control over voltage problems that can be seen on the fully ungrounded system.

4. Reactor Grounded Systems

The last of the current methods is inductive reactance grounding using a Neutral Grounding Reactor. These devices insert between the system’s neutral point and ground, similar to resistance grounding. Solid non-arcing type faults best apply it. Arcing faults that are very typical on many distribution systems cause resonant overvoltages, so you must consider this in their application.

Conclusion

In conclusion, you need to consider many factors when choosing the best or required method of neutral grounding with the intention of providing maximum circuit continuity. Regulations (NEC, IEEE, etc.), and safety considerations are the priority. Other important items for consideration where not directly governed by regulations include the following items:

- Environmental Considerations

- Typical system fault types

- Maximum system fault current

- Cost of equipment

- Other location specific needs

- Project budget

Considerations of all the above factors and methods give modern day system designers better grounding options. This can result in better overall solutions to circuit continuity and reliability issues. Before deciding on a solution, review the numerous standards and technical papers that discuss these applications and their use in more detail.

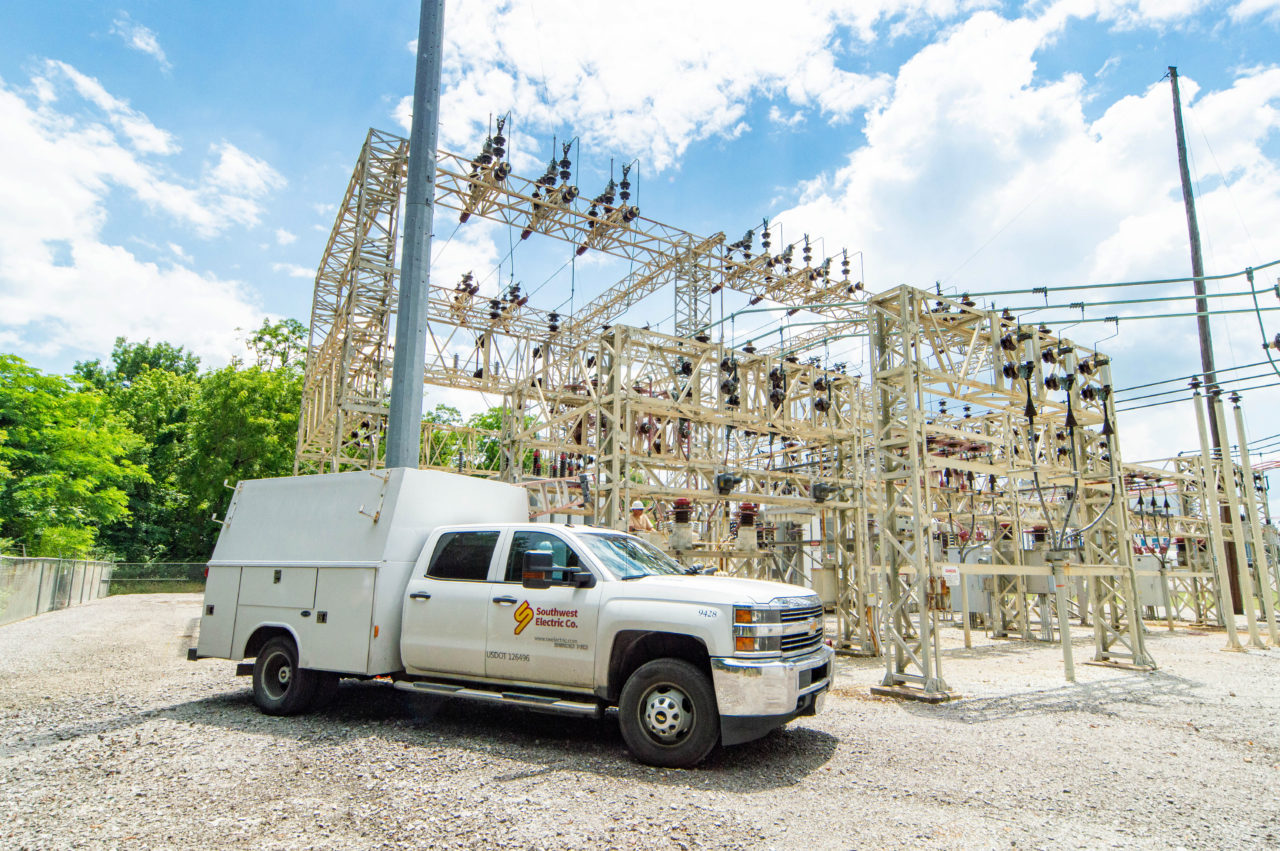

For a professional evaluation and guidance, contact Southwest Electric Co. We can help you select the best method to protect your electrical system.

Continued Education

We encourage you to continue researching the best ways to select and maintain your equipment. Visit our library of articles to discover important information about transformers, switchgear, motors, field services, and more!

Visit our YouTube channel to stay up to date on our latest industry videos!