By Steve Reasonover, General Manager - Motors

What is Dyno Testing?

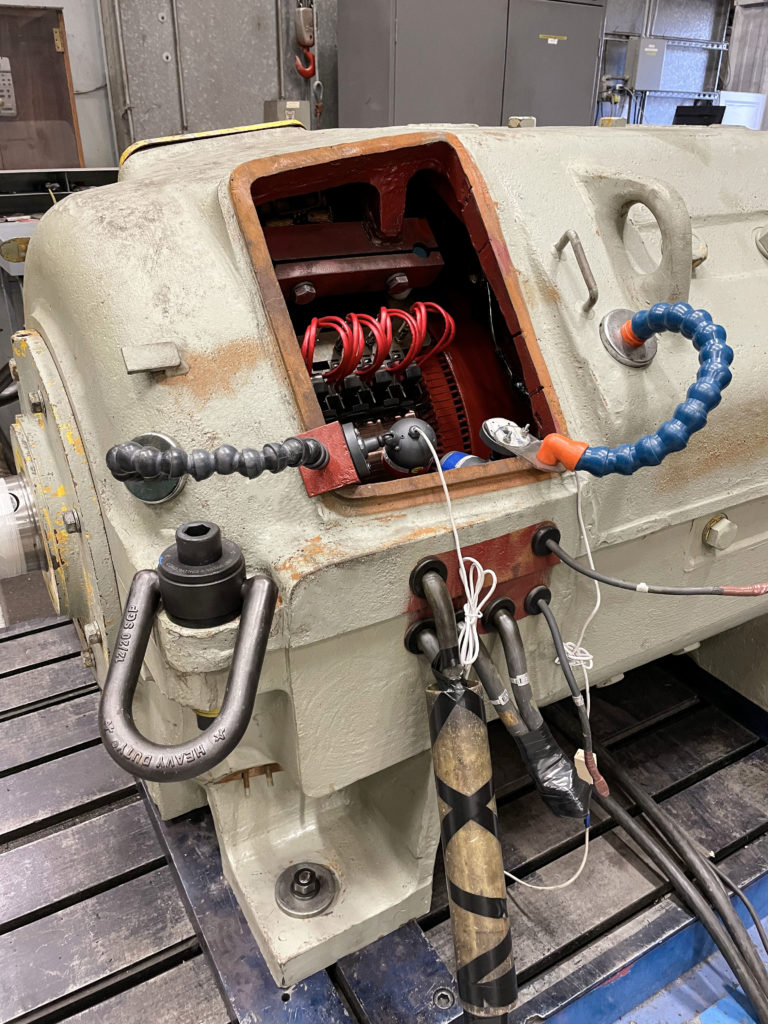

Dynamometer testing, more commonly known as dyno testing, is a type of motor load test. It detects issues with motors that only surface while under load and ensures that all the electrical properties of a rebuilt motor are correct. This can only be confirmed by putting a minimum of 30-50% load on a motor and running it.

Dyno testing is primarily performed on DC motors. Most often in our shops, we see DC motors from large manufacturing plants like steel mills, paper mills, rubber factories, and plastics factories benefit from this type of load testing.

Why Dyno Test?

Dyno testing is performed at the request of the customer in order to help prevent extra costs and downtime after a motor is back at their facility. Some customers even require this test based on their facility’s repair policy. When a motor is brought in for reconditioning or repair, the equipment is disassembled, worked on, and reassembled. With dyno testing, we get the opportunity to identify any new or resurfacing issues with the motor while still under our shop’s roof before it is transported and installed back in its home facility. This process can potentially eliminate extra costs and downtime that could occur if a problem were to be detected during or after installation.

Watch the dyno test process:

Steps to Dyno Testing

- Before connecting a motor to the dynamometer, we perform all tests under no load. This identifies any problems that are not solely caused under load.

- The motor is then installed, aligned, and connected to the dynamometer machine.

- The motor is then run under 30-50% of load for several minutes, while we monitor and record performance.

- Once the test is complete without detected errors, we disconnect and remove the motor from the dynamometer machine and the motor is that much closer to returning to customer. If errors are detected, we take the opportunity to correct them & re-test before install.

Dyno Testing at SWE

At Southwest Electric Co., we offer repair and maintenance for almost any type of industrial motor, with the ability to service motors of up to 100 tons. We pride ourselves on the high quality and reliability of our repairs. We perform all the work under our roof—nothing is contracted out to other vendors. Our repair shop runs 24 hours/day, where our skilled craftsmen maintain a high standard of technical excellence. This commitment to excellence includes extensive documentation of any repairs needed or done. This gives you a thorough set of records to reference when future work is required. We pride ourselves on providing exceptional industrial motor solutions to every customer, every time. Learn more about how we can help meet your needs. Give us a call, email, or request a quote using the button below to get in touch with us today.